Errore nel formato dell'e-mail

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Notizia

From Design to Production: The Journey of OEM Stainless Steel Stamping Parts

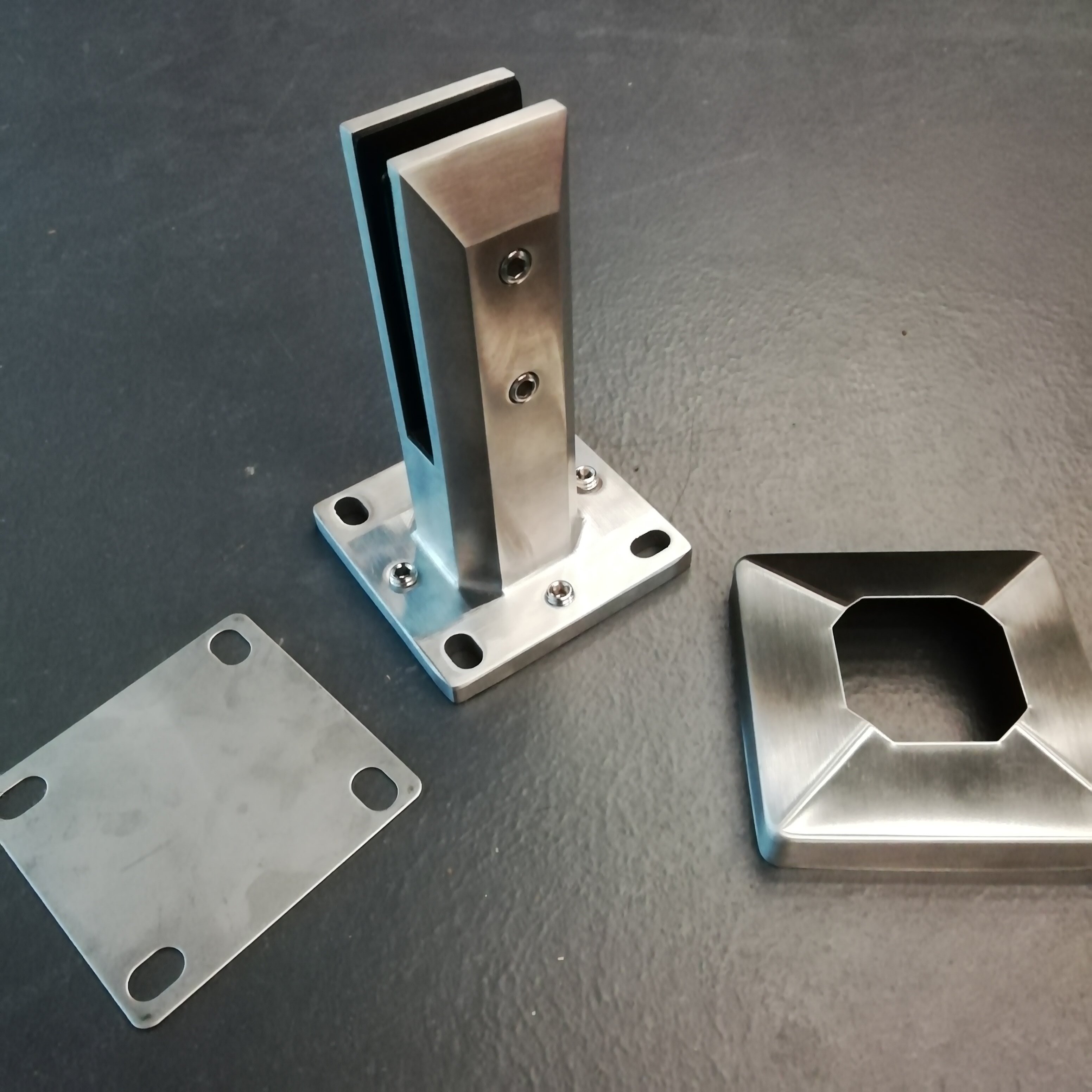

OEM stainless steel stamping parts play a crucial role in various industries, providing customized solutions for a wide range of applications. From the initial design phase to the final production, the journey of these parts involves careful planning, precision engineering, and efficient manufacturing processes. In this blog post, we will explore the journey of OEM stainless steel stamping parts, highlighting the importance of design, the intricacies of the stamping process, and the benefits they bring to different industries.

Design Phase:

The journey of OEM stainless steel stamping parts begins with the design phase. This stage involves collaboration between engineers, designers, and clients to understand the specific requirements and desired outcomes. Design considerations include material selection, dimensions, tolerances, and functionality. Advanced computer-aided design (CAD) software is used to create detailed 2D and 3D models, allowing for precise visualization and analysis of the part before moving forward.

Tooling and Prototyping:

Once the design is finalized, the next crucial step in the journey of OEM stainless steel stamping parts is tooling and prototyping. Tooling involves the creation of specialized dies and molds that will be used in the stamping process. These tools are meticulously crafted to ensure accuracy and consistency in the production of the stamped parts.

Tooling begins with the selection of the appropriate materials for the dies and molds. Factors such as the complexity of the part, the desired finish, and the expected production volume are taken into consideration. The chosen materials, often hardened steel or carbide, are then carefully machined and shaped to match the design specifications.

The creation of the dies and molds requires a high level of precision and expertise. Advanced machining techniques, such as computer numerical control (CNC) machining, are employed to ensure the accuracy and quality of the tooling. The dimensions and tolerances of the dies and molds must align perfectly with the design requirements to achieve consistent and reliable stamped parts.

Stamping Process:

The stamping process is the heart of the journey of OEM stainless steel stamping parts. It involves the use of specialized stamping machines and presses to shape and form the stainless steel sheets into the desired parts. This process requires precision and expertise to ensure that each stamped part meets the required dimensions and tolerances.

The first step in the stamping process is the preparation of the stainless steel sheets. The sheets are carefully selected based on their thickness, strength, and other material properties. They are then cut into the appropriate size and shape to fit the dies and molds.

The stamped parts are created by feeding the stainless steel sheets into the stamping machine. The machine consists of a press, which exerts pressure on the sheets, and the dies, which are mounted on the press. The dies are designed to cut, bend, or shape the material according to the desired design specifications.

The stamping process requires precise control of the pressure, speed, and timing to achieve accurate and consistent results. The press applies the necessary force to deform the stainless steel sheets, transforming them into the desired shape. The dies guide and control the movement of the material, ensuring that each stamped part is formed with the required dimensions and tolerances.

Stamping machines can be operated manually or automatically, depending on the complexity and volume of production. Automatic stamping machines offer higher efficiency and productivity, as they can process multiple sheets simultaneously. However, manual operation allows for more flexibility and control, especially for intricate or custom designs.

Quality Control:

Quality control is an integral part of the journey of OEM stainless steel stamping parts. Throughout the production process, rigorous inspections and tests are conducted to ensure that the parts meet the highest standards. This includes dimensional checks, surface inspections, and material analysis. Quality control measures help identify any deviations or defects, allowing for adjustments and improvements to be made before the final products are delivered.

Applications and Industries:

OEM stainless steel stamping parts find applications in a wide range of industries, including automotive, aerospace, electronics, and construction. These parts are used in components such as brackets, connectors, enclosures, and electrical contacts. The versatility of stainless steel allows for its use in various environments, providing durability, corrosion resistance, and aesthetic appeal. OEM stamping parts offer customized solutions that meet the specific requirements of each industry, contributing to improved performance and efficiency.

Benefits and Advantages:

The journey of OEM stainless steel stamping parts brings several benefits to industries and manufacturers. Firstly, the customization options allow for the creation of parts that precisely fit the intended application, optimizing functionality and performance. Secondly, the stamping process enables high-volume production with consistent quality, ensuring cost-effectiveness and timely delivery. Additionally, stainless steel’s durability and resistance to corrosion make it a reliable choice for demanding environments.

Conclusion:

The journey of OEM stainless steel stamping parts involves a meticulous process from design to production. Through careful planning, precision engineering, and efficient manufacturing, these parts provide customized solutions for various industries. From automotive to aerospace, OEM stamping parts contribute to improved performance, durability, and cost-effectiveness. As technology advances, the journey of OEM stainless steel stamping parts continues to evolve, meeting the ever-changing demands of modern industries.